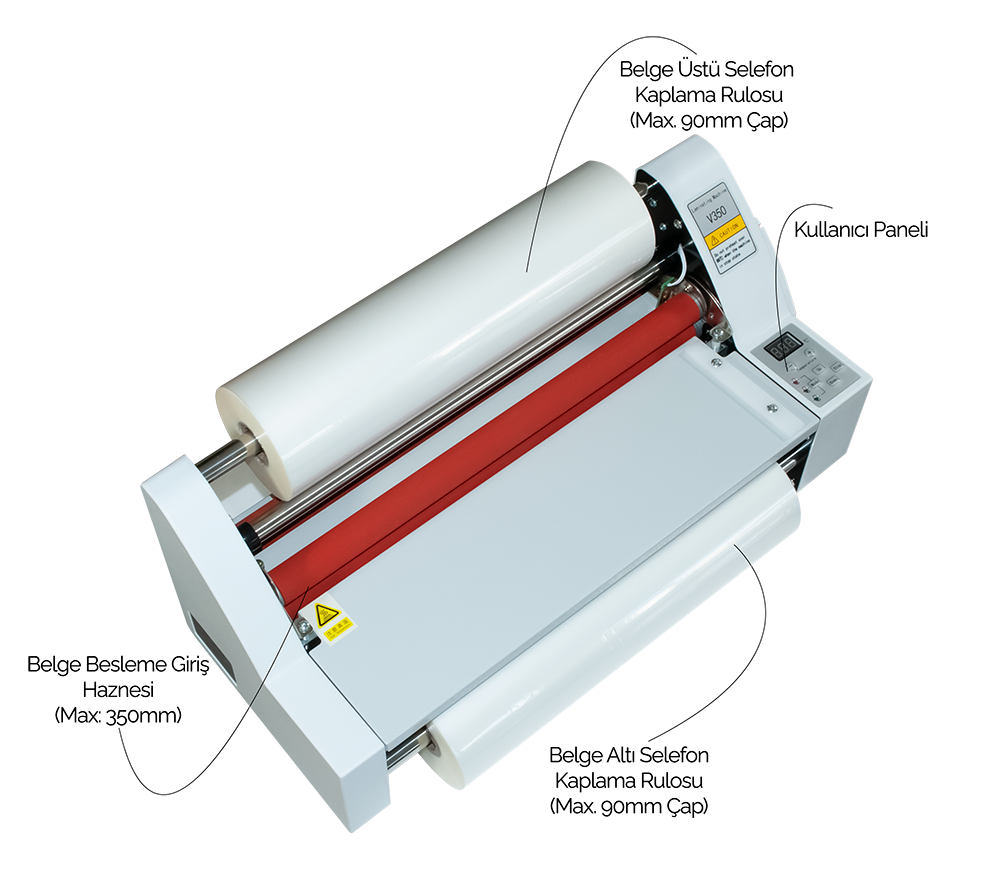

MÜHLEN V350

A3 Cellophane Coating Machine

Single or Double-Sided

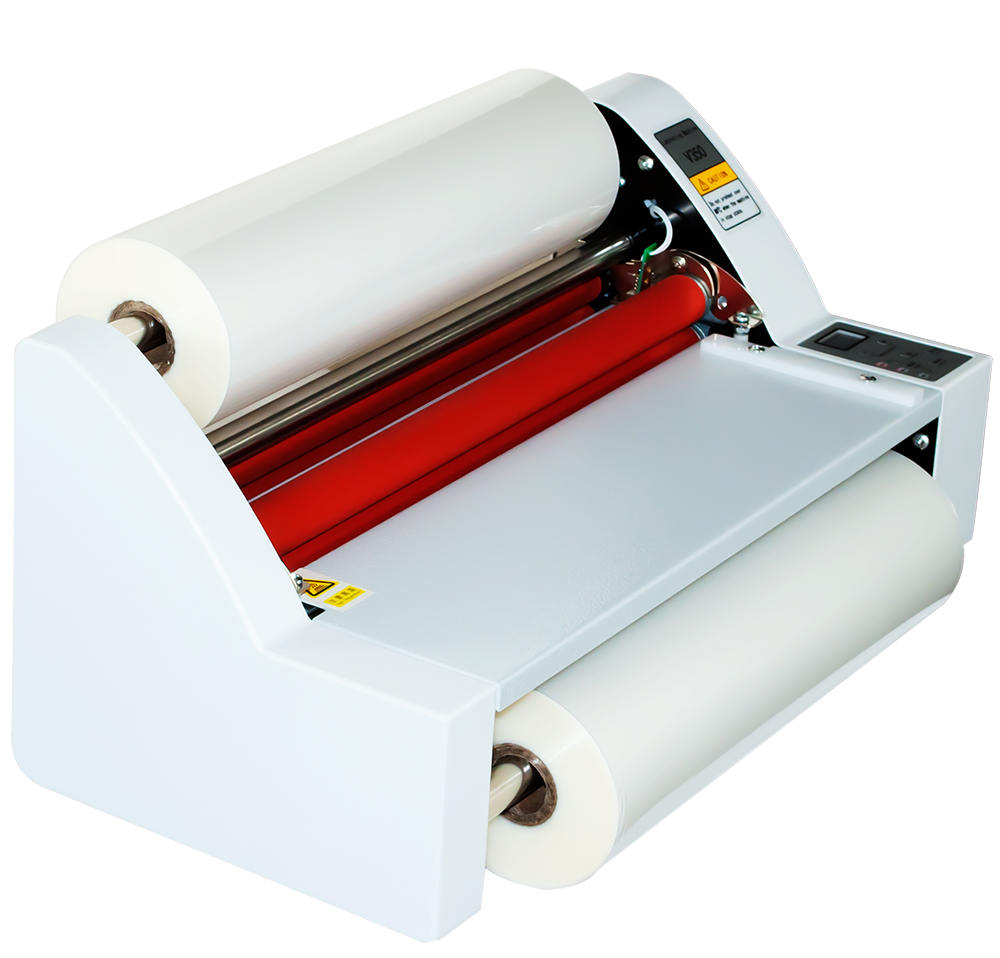

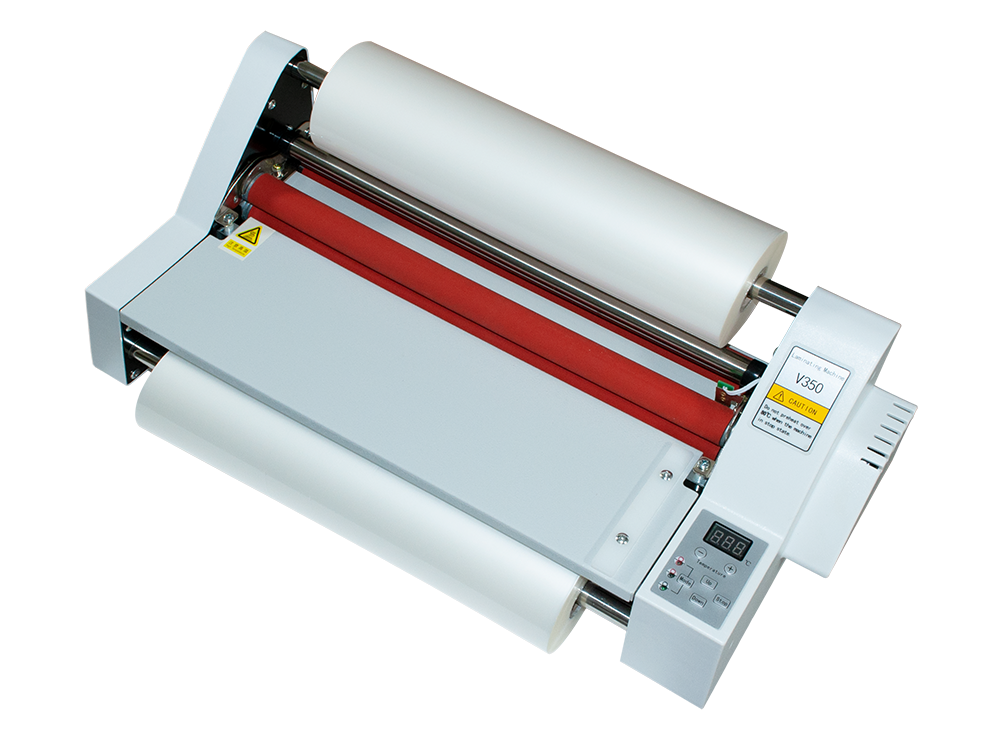

The MÜHLEN V350 model fully automatic laminating machine has the ability to laminate documents, cards, or images at high speed, with the option for either single-sided or double-sided lamination. Using the “Mode” button on the user panel, the user can perform either single or double-sided hot lamination, or even cold lamination.

Large Feeding Tray

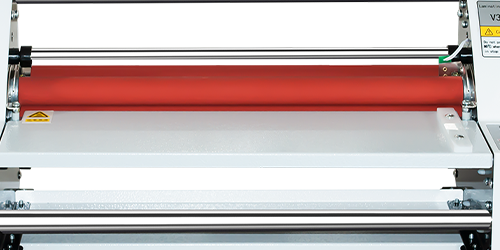

The MÜHLEN V350 model features a special 4-cylinder system and a 350 mm wide feeding tray. It can laminate A3 and A4 size documents with ease, while also being able to laminate multiple A5 or smaller documents simultaneously, without wasting any film.

High Speed

The model has a maximum speed of 1.1 meters per minute. The MÜHLEN V350 laminating machine can start by determining the feeding direction using the forward/reverse buttons on the user panel. To stop the operation, the “Stop” button on the panel is used.

-

UNIQUE CELLOPHANE COATING

The model is capable of coating cellophane or PVC film with perfect printing in one pass. The model can be coated with hot or cold cellophane as well as PVC lamination film. As the user can choose glossy cellophane coating, the user can also choose matte cellophane coating.

-

20 MICRONS TO 250 MICRONS

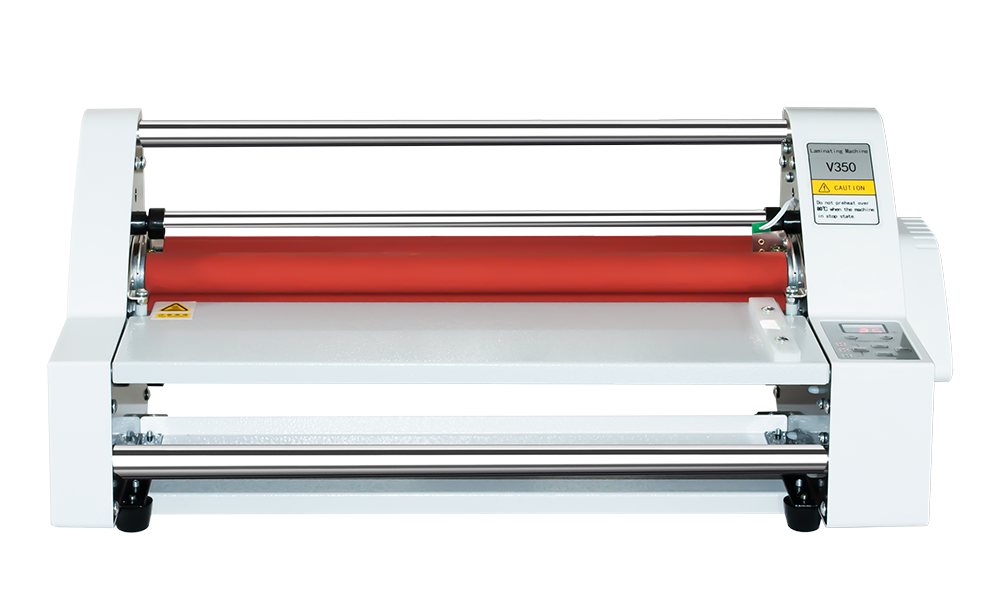

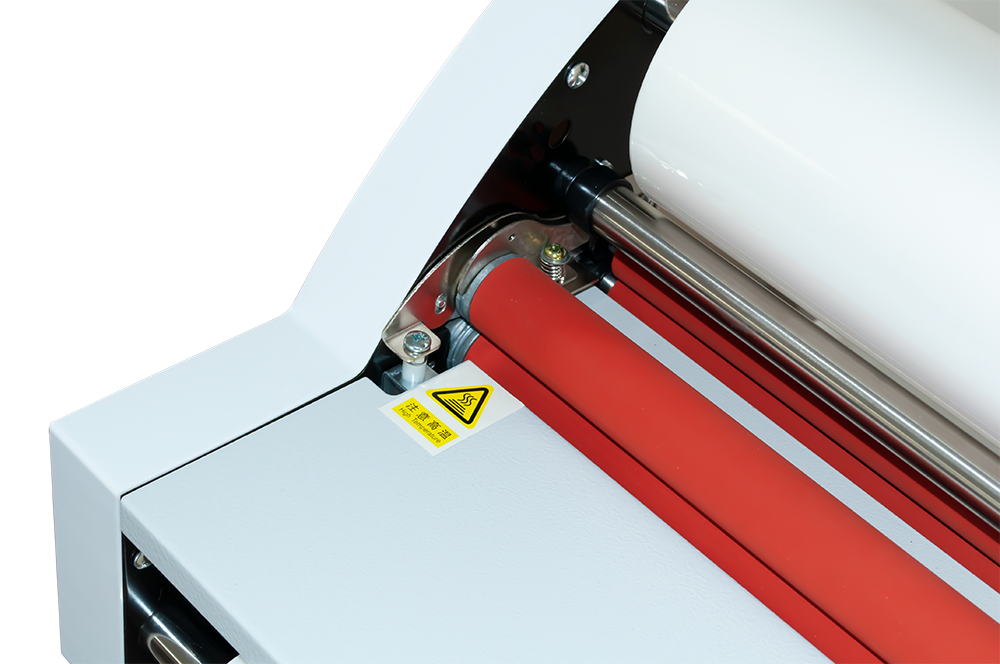

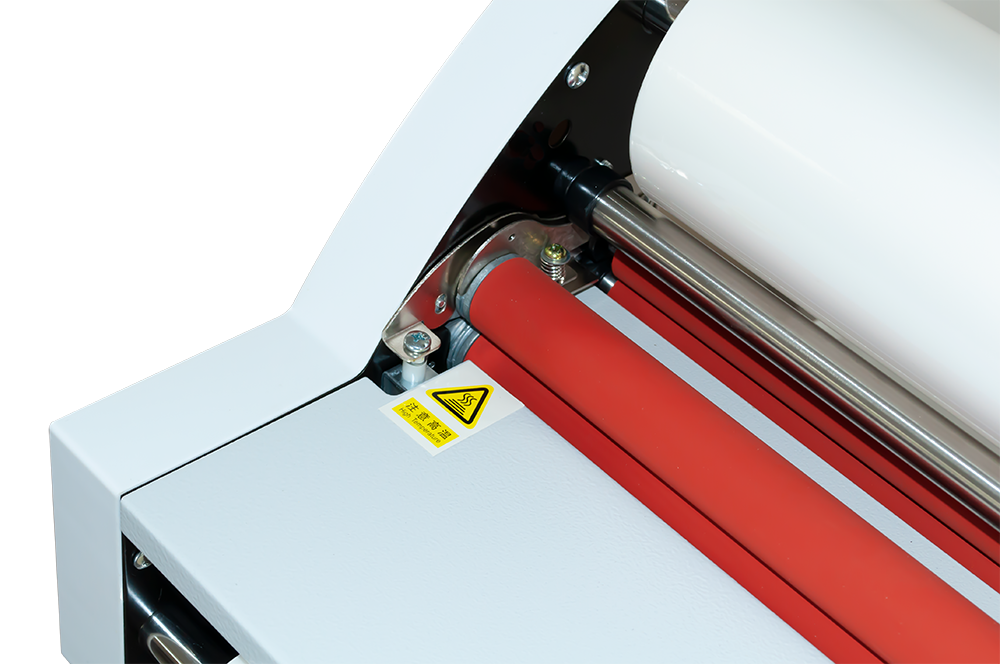

The model, which combines all coatings from the thinnest cellophane film to the thickest PVC lamination film in a single machine, can coat all films and cellophane from 20 microns to 250 microns (20~250mic.) perfectly and in one go. If desired, the user can narrow and open the gaps between the rollers by means of roller adjustment screws.

-

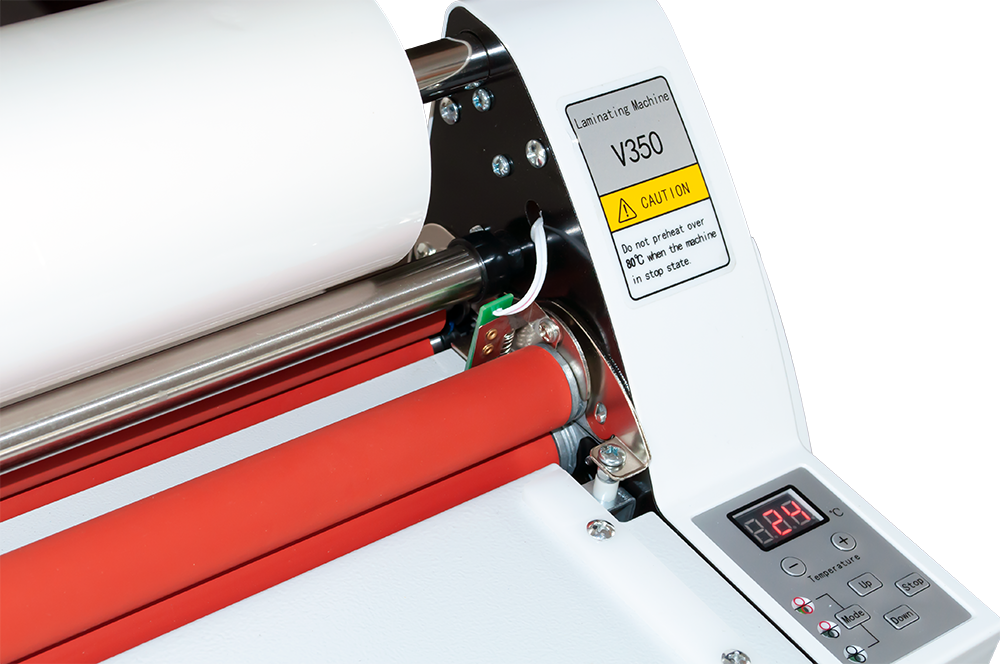

LONG LIFE COMPONENTS

The model, whose skeleton and internal parts system is completely metal (the rollers are made of special polyurethane material), is designed to work with the efficiency of the first day without losing performance for many years. The gear structure accompanying the powerful and functional motor system, as well as the electronic components, work perfectly under all kinds of heat and humidity conditions.

-

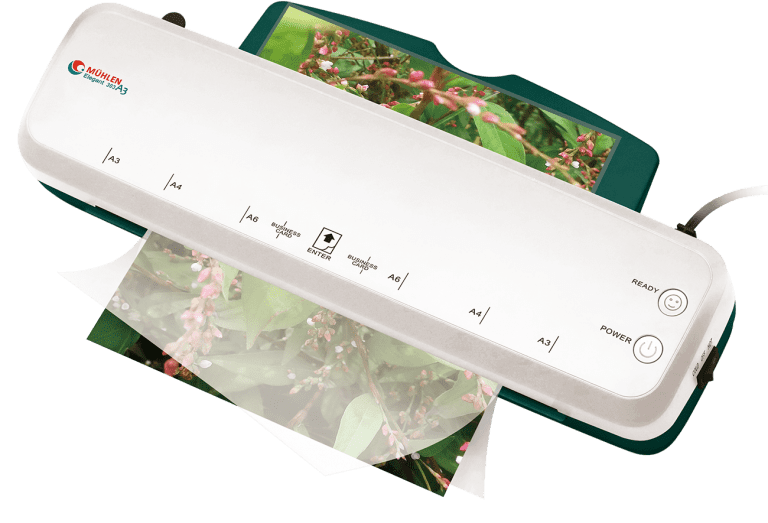

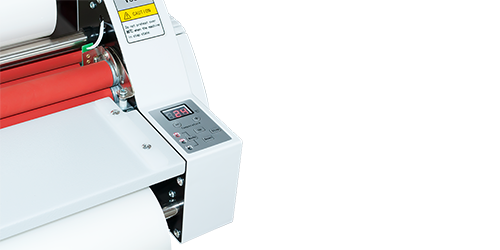

UNIQUE CONTROL PANEL

The model helps you to enter the heat target with the “+” and “-” buttons, while at the same time the LED panel shows both the current heat and the targeted heat. Apart from this, the “Mode” button can be used to set one or both sides of the document or cold cellophane coating, while the “Stop” button can stop it. The “Up” and “Down” buttons are used to determine the input and output direction of the cellophane and to start.

Technical Specifications

-

Cellophane and film coating between 20~250 microns

-

Single or double sided cellophane coating feature

-

350 mm feed opening (A3 and smaller)

-

Electronic temperature adjustment between 0~180°

-

Suitable Material Thickness: Between 0.1~5 mm

-

Audible and written signal when the appropriate temperature is reached

-

Hot and cold cellophane and PVC coating

-

Cellophane or PVC lamination film

-

Ability to use continuous roll cellophane form

-

A3, A4, A5... PVC lamination coating

-

Ability to use rolls up to 90mm diameter

-

Available films: BOPP, PET, PVC

-

Glossy and matte cellophane coating

-

Bi-directional film input and output

-

Film coverage speed of 1.1 meters per minute

-

Metal interior parts and skeleton system

-

Perfect cellophane with every pass

-

Unique user control panel

-

2 internally heated cylinders

-

4 special production cylinders

-

Film roll inner diameter: 2.54cm

-

LED heat indicator display

-

Motor power 180W

-

24 Month warranty

Advantages

-

Single & Double sided cellophane coating

-

Coverage speed of 1.1 meters per minute

-

For A3 and smaller sizes

-

PVC laminating film coating

-

20~250 micron coating

Physical Properties

-

Machine Weight: 7kg.

-

Parcel Weight: 8 kg.

-

Machine Dimensions: 53x21x22cm

-

Parcel Dimensions: 60x29x30cm

Featured Products

All Our Products