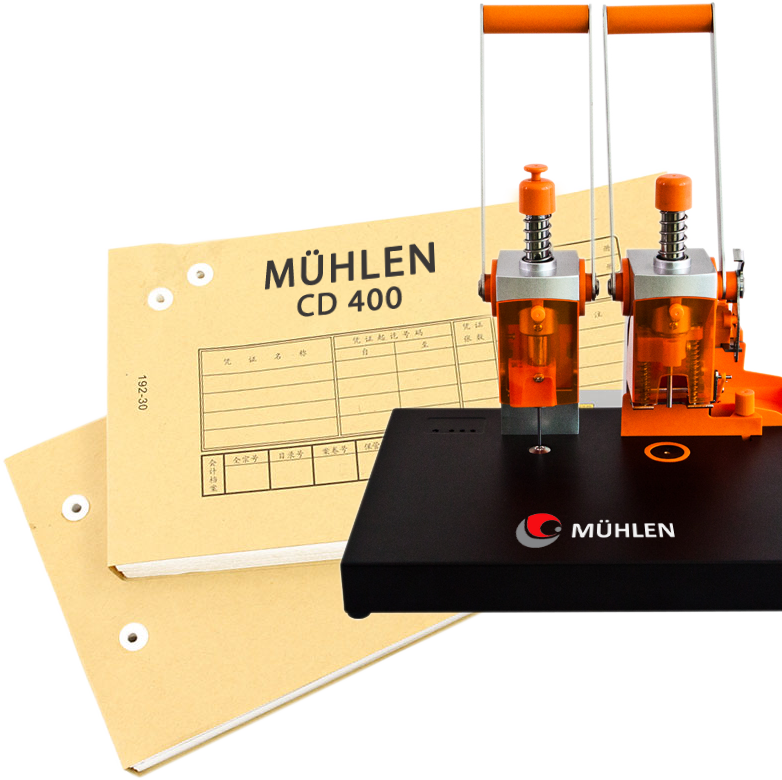

MÜHLEN CD 400

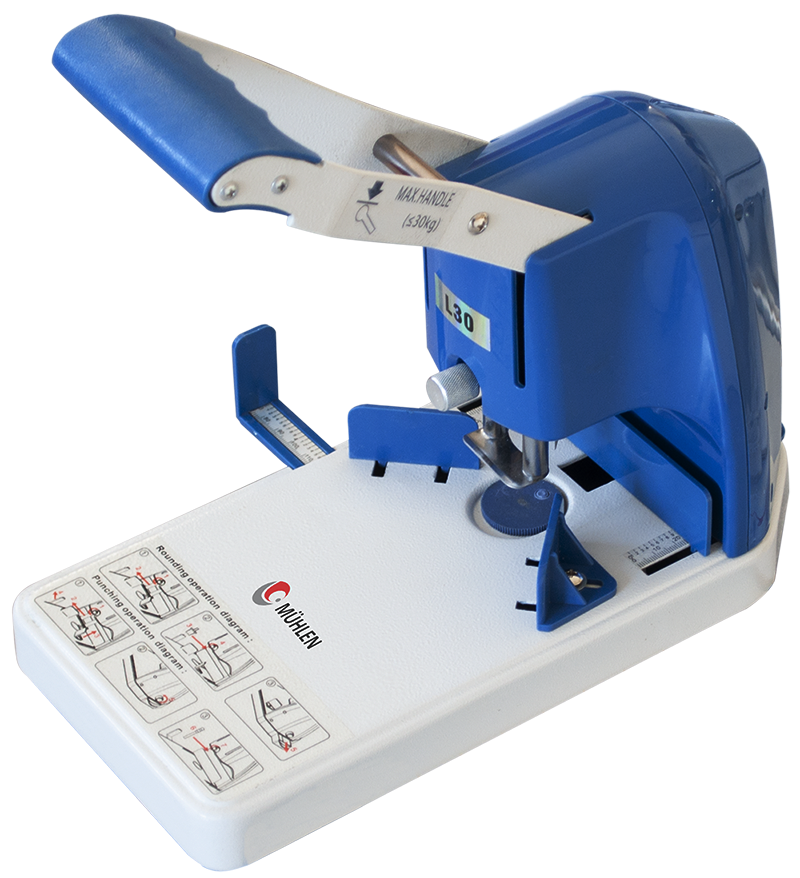

Thermal Punching and Riveting Machine

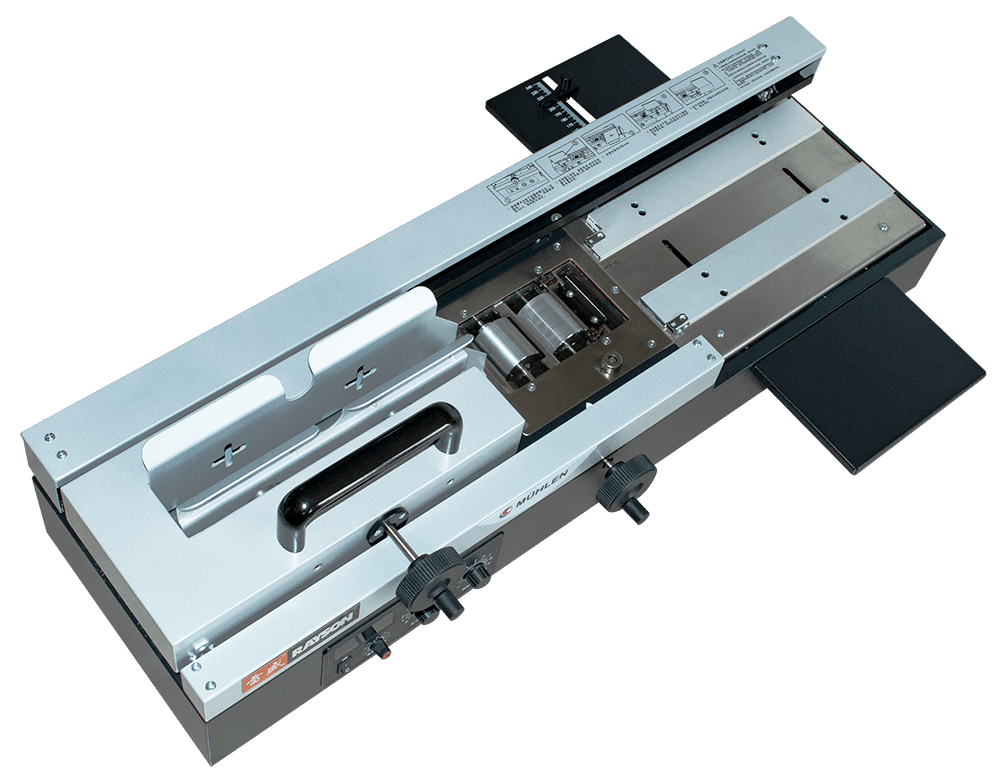

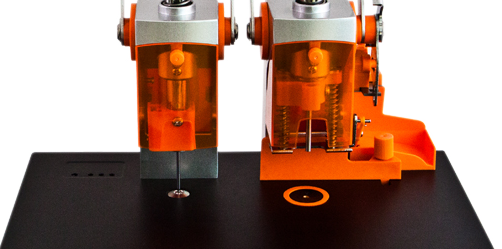

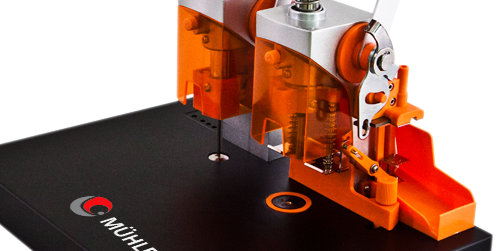

The MÜHLEN CD 400 riveting machine features an adjustable front margin. While the left chamber performs laser punching, the right chamber carries out riveting at the desired size. This financial binding machine is used to bind documents such as invoices, forms, and product catalogs. The MÜHLEN CD 400 model performs nylon tube pressing and riveting binding operations.

This model handles the entire process separately: punching, binding, automatic PET tube insertion, automatic tube cutting, and pressure riveting. It is widely used for product catalogs, banking, securities, insurance, telecommunications, schools, businesses, financial documents, invoices, account sheets, notices, magazines, page files, folders, drawings, papers, book pages, and similar binding applications.

The electrically operated MÜHLEN CD 400 model becomes ready for binding in as little as 15 seconds. It then performs the punching operation at the desired position on the document with the help of a mechanical lever, inserts the plastic tube into the punched hole with its built-in mechanism, and completes the riveting process using thermal pressure.

Model No: Mühlen CD 400 Thermal Riveting and Binding Machine

-

UP TO 40 MM RIVETING CAPABILITY

MÜHLEN CD 400 is capable of riveting and binding documents of any thickness between 1~40 mm. The machine's thermal riveting nail reaches the required temperature in as little as 15 seconds and can perform the riveting process. In addition, the structure of the core axis provides a long-lasting riveting system.

-

STEEL BODY AND MECHANICAL SYSTEM STRUCTURE

The model is designed for many years of service without loss of performance thanks to its steel body, steel internal parts and heat-resistant steel riveting nail. The robust drilling and riveting system is mechanically suitable for high work intensity.

-

AUTOMATIC RIVET TUBE TAKE-UP AND AUTOMATIC CUTTING

The machine warns the user with sound and light when it is ready for each operation or when each operation is finished. As such, after placing the rivet tubes in the chamber, the machine performs the riveting and tube threading by itself. Then the machine cuts the tube at the required level and finishes the riveting process and warns the user with sound and light.

-

AUTOMATIC POWER SAVING MODE

MÜHLEN CD 400 thermal riveting machine saves energy by automatically switching to sleep mode after 25 minutes of inactivity. At the same time, the user can manually switch to power saving (sleep) mode by pressing and holding the power button for 3 seconds. The model with 120 Watt operating power saves energy thanks to this feature.

Technical Specifications

-

Maximum Drilling and Riveting Thickness: 400 mm

-

Material Used: Plastic Tube (Plastic Pet)

-

Heating and Riveting: Automatic

-

Removable Waste Bin Container: Yes

-

Plastic Tube Insertion: Automatic

-

Plastic Tube Cutting: Automatic

-

Riveting Hole Drilling: Mechanical Arm Assist

-

Hole Size: 5 mm

-

Margin Adjustment: 10-25

-

Power: 120 W

-

Warranty Period: 24 Months

Advantages

-

400 mm Drilling and Riveting Thickness

-

Automatic Rivet Tube Receiving and Cutting

-

Automatic Plastic Tube Insertion

-

Manual Margin Adjustment

-

Automatic Power Saving Mode

Physical Properties

-

Parcel Size: 456x375x337

-

Gross Weight 11.1 Kg.

-

Net Weight: 10 Kg.

-

Power: 120 Watt

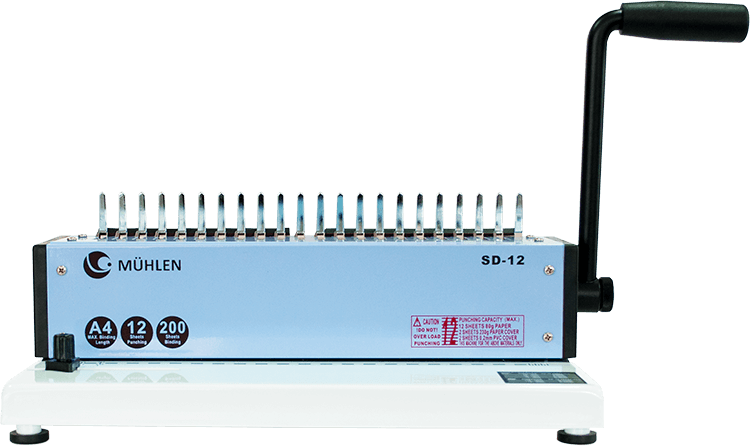

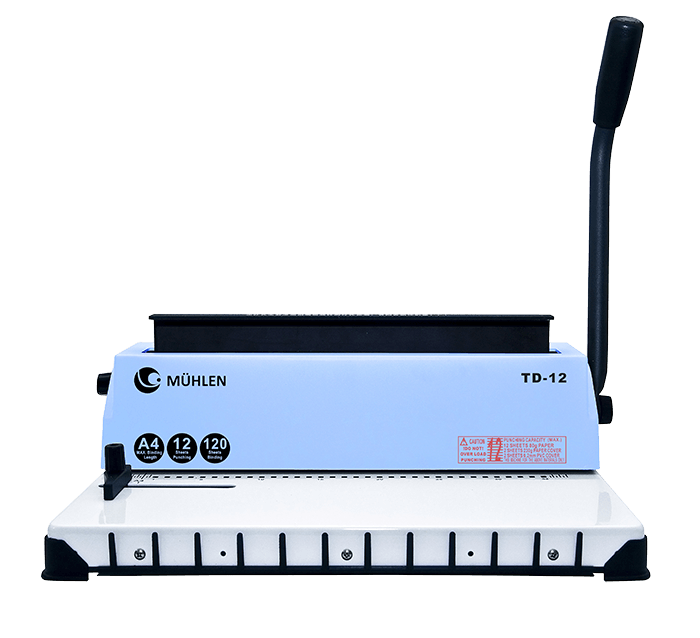

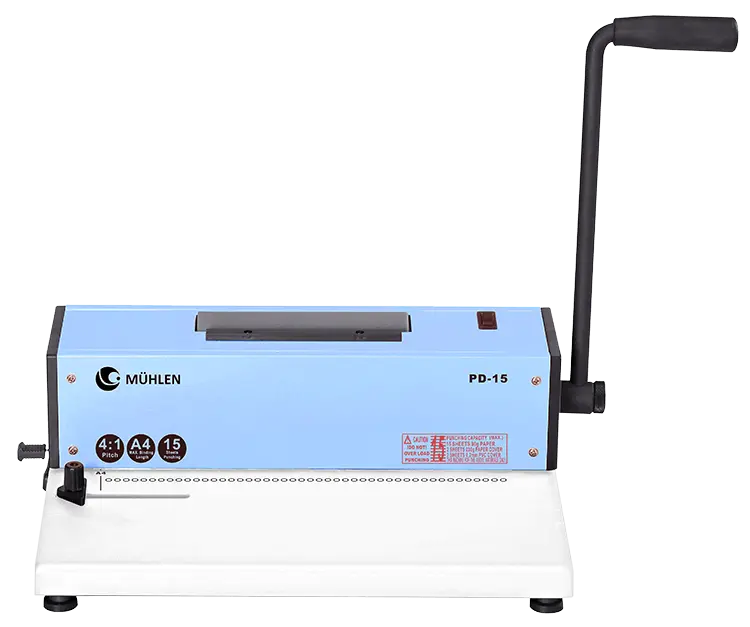

Featured Products

All Our Products